What is Supply Chain Planning ? This is a question some might ask when they hear the term supply chain and planning is the additional suffix added to explain the meaning in total. To understand Supply Chain Planning, we need to first understand what a supply chain means?

What is Supply Chain?

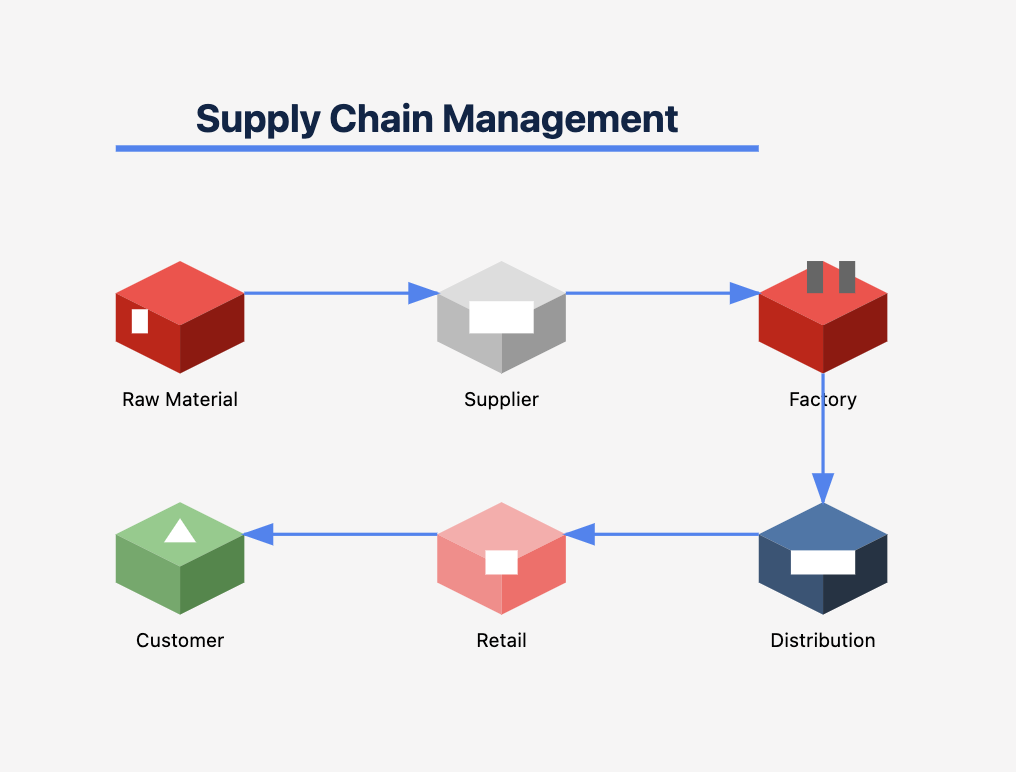

Supply Chain is movement of goods primarily physical goods from manufacturers to the end consumers. This whole chain of flow of goods typically goes through multiple steps and thereby the name supply chain!

All supply chains need not look like the above and can be a subset but you get the idea of what we are talking about!

Like the movement of data from servers to the client side in case of a web app, physical products that you consume, which can be edible items like Rice, Pasta, sauces etc or devices like your phone or even a car, go through a process as mentioned above.

Why Plan Supply Chains?

Supply chains thereby are critical in todays modern world. With extreme competition and need for efficiency in the business. It’s critical for a firm to get their supply chains correct!

A breakdown in some intermediate step such as manufacturing can be mean. The firm not being able to meet it’s demand and thereby losing out on sales and in the long run, trust of the consumers.

Similarly, over production of goods might mean, there is excess inventory on the retail side and might not sell fast. This forces the company to hold these goods or sell them at a lower price to sell off the excess. Both these are not good either lowering margins or forcing the company to block a lot of inventory as working capital.

A retail company’s efficiency is often measured in terms of inventory turn over ratio. Thereby how long does the firm hold the inventory before selling it off, often indicating the efficiency of supply chain/retail process etc.

All this means, there is a need to efficiently plan the flow of goods through the supply chain. This is to be able to meet the demand as closely as possible while at the same time, having the agility to react fast!

Key Metrics

Now that we know what a supply chain is and the need to efficiently plan those. These are some of the key metrics/definitions involved in the process!

- Lead Time: The time between identification of an action and how long it takes to get it executed. E.g. We identify that need 100 more units of a product at a store. A lead of 7 days means, it will take us 7 days to restock the 100 units we identified. Lower the lead time, more efficient are the process and robustness of the supply chain!

- Demand Forecasting/Sensing: Before we restock goods and make a request, we need to anticipate the demand. Through various signals including historical precedence and future changes expected. This is a critical step, since and any error here compounds back through the supply chain!

- Hub/Spoke: It’s a very popular kind of distribution model. Where in inventory is typically stocked at a super distribution level before being delivered to the spokes aka retail outlets. This helps streamline the supply chain process.

- Replenishment: Against the demand forecasted/sensed, we need to replenish the goods through the chain. A good forecast but bad replenishment means, we are accurate in anticipating demand but poor at getting the goods to the right places.

Why is Supply Chain Critical Now?

In today’s age where we have made plenty of strides in how to discover and deliver information through distributed systems, recommendations etc. There is a need to evolve the quality of supply chains as well. So much so that this is becoming the key differentiator between firms. A robust supply chain ensures a fast reacting business that is able to keep tight operations!

Think Amazon, Costco and the upcoming stalwarts in Q-commerce in India!

Q-commerce is fundamentally a supply chain revolution! It’s the ability to move goods so fast so as to be being able to anticipate and full-fill demand. That has disrupted the entire e-commerce space in India.

Reach out at admin[at]startupanalytics.in